Inventory adjustments

In any warehouse management system, the recorded inventory counts in the database might not always match the actual inventory counts in the warehouse. The discrepancy between the two counts can be due to theft, damages, human errors, or other factors. As such, inventory adjustments must be made to reconcile the differences, and ensure that the recorded counts in the database match the actual counts in the warehouse.

In Odoo, inventory adjustments can be accessed through .

The Inventory Adjustments page shows all products that are currently in stock. Each line contains the following information:

Product

Lot/Serial Number

On Hand Quantity

Add a new line

To add an inventory adjustment line, click Create and fill in the Product and Counted Quantity fields. Then click Save.

At this stage, the count is recorded but not yet applied. Meaning the quantity on hand is not yet updated to match the new Counted Quantity.

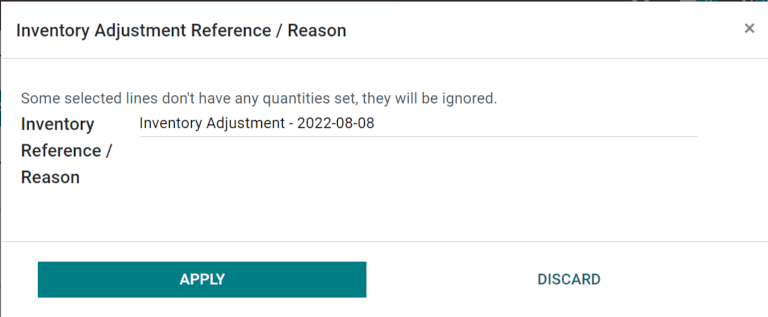

To apply the new Counted Quantity, click Apply on the line or the Apply All button on the top of the page. If Apply All is clicked, a reference or reason can be entered before clicking Apply.

Count products

Counting products is a recurring activity in a warehouse. Once a count is complete, go to to update the Counted Quantity column for each product line.

If a count matches the On Hand Quantity recorded in the database, click on Set, which will copy the value in the On Hand Quantity field and paste it in the Counted Quantity field. A move with 0.00 Quantity Done will be recorded in the product’s inventory adjustment history.

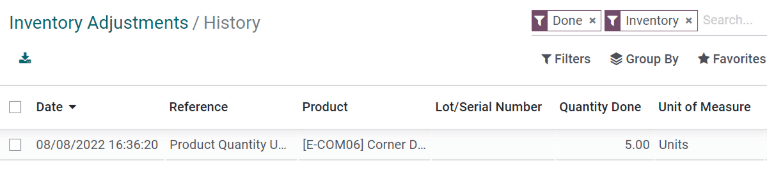

If a count does not match the On Hand Quantity recorded in the database, record the count in the Counted Quantity field. When Apply is clicked, a move with the difference between the On Hand Quantity and Counted Quantity will be recorded in the product’s inventory adjustment history.

Note

Sometimes a count occurs, but can not be applied in the database right away. In the time between the actual count and applying the inventory adjustment, product moves can occur. In that case, the On Hand Quantity in the database can change and will not be consistent with the counted quantity. As an extra caution measure, Odoo will ask for confirmation before applying the inventory adjustment.

Plan counts

Each inventory adjustment line contains the following information:

Scheduled Date: the date at which a count should be made.

User: the person in charge of the count.

Accounting Date: the date at which the adjustments will be accounted. The column is hidden by default, but can be made visible by opening the column options icon.

Important

In the Barcode app, users can only view counts assigned to them that are scheduled for today or earlier.

To plan big counts, select the desired product lines on the Inventory Adjustments page. Then, click Request a Count and fill in the following information:

Inventory Date: the planned date of the count.

User: the user responsible for the count.

Accounting Date: the date at which the inventory adjustment will be accounted.

Count: to leave the On Hand Quantity of each product line blank, select Leave Empty. To prefill the On Hand Quantity of each product line with the current value recorded in the database, select Set Current Value.

Finally, click Confirm to request the count.

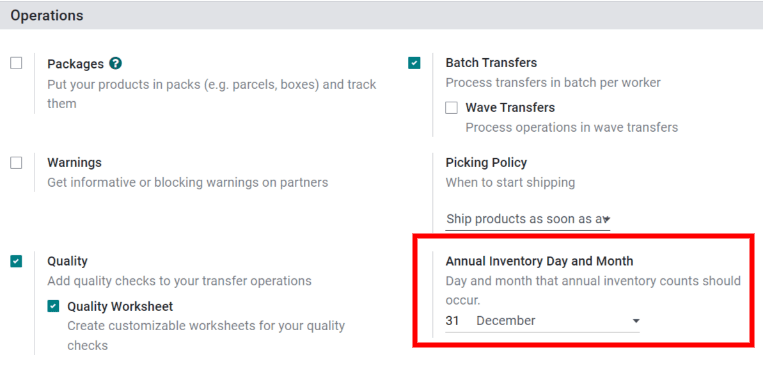

By default, after an inventory adjustment is applied, the scheduled date for the next count is the 31st of December of the current year. To modify the default scheduled date, go to and change the date in the Annual Inventory Day and Month setting.